You’ll need to follow strict NFPA 99 protocols when managing nitrous oxide tanks in mental health facilities. Secure tanks upright using chains or approved stands in a well-ventilated area with temperatures between -20°F and 125°F. Install dual ventilation zones, real-time gas monitors, and maintain thorough staff training for emergency responses. Guarantee proper documentation of all safety checks and establish clear evacuation procedures. Understanding the full safety framework will substantially boost your facility’s compliance and readiness.

Essential Storage Requirements and Tank Positioning

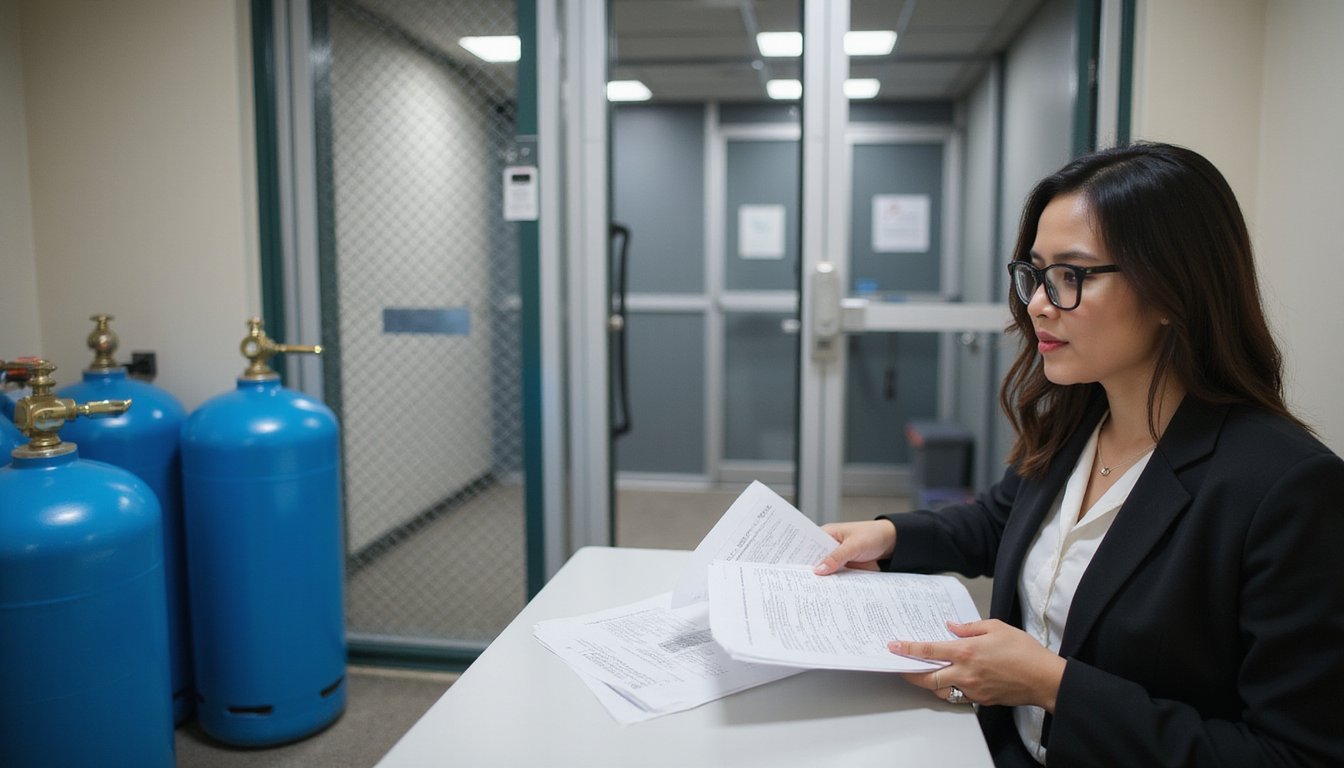

While proper storage of nitrous oxide tanks forms the foundation of safety in mental health facilities, specific requirements for tank positioning and securing methods must be strictly followed. You’ll need to store cylinders upright and secure them with chains or approved stands to prevent tipping. Being a colorless gas, nitrous oxide requires clear labeling and identification systems on all tanks. Maintain temperatures between -20°F and 125°F in a cool, dry environment away from direct sunlight. Your storage room must have 1-hour fire-rated walls and ¾-hour fire-rated doors, with mandatory emergency power systems in place. The storage area requires a proper cryogenic fluid manifold system for safe gas distribution. The area must be well ventilated to prevent gas accumulation in case of leaks.

Implement regular inventory tracking and cylinder monitoring protocols. You must segregate full, partial, and empty tanks while restricting access to authorized personnel only. Keep tanks away from ignition sources, flammable materials, and electrical machinery. Install proper cylinder racks and inspect securing devices regularly to guarantee continuous safety compliance.

Ventilation Systems and Air Quality Control

Beyond secure storage protocols, proper ventilation systems serve as your primary defense against nitrous oxide exposure in mental health facilities. You’ll need to implement dual ventilation zones with both general room ventilation and local exhaust systems near gas emission points. Your airflow optimization must include low-wall intakes and ceiling exhausts to prevent gas accumulation. Following NFPA 99 guidelines, your facility must maintain strict ventilation requirements through properly positioned intake and exhaust systems.

Deploy gas monitoring techniques through real-time sensors that alert staff when concentrations exceed 25 ppm. Since nitrous oxide is a nearly odorless gas, facilities must rely heavily on monitoring systems rather than human detection. You must guarantee your scavenging systems vent directly outside, avoiding any recirculation into fresh air intakes. Locate local exhaust hoods near patient stations and maintain balanced supply/exhaust ratios to prevent gas migration. Remember to run continuous airflow during and after gas use, and conduct regular system diagnostics to verify your ventilation’s effectiveness.

Temperature Monitoring and Environmental Controls

Precise temperature control stands at the forefront of safe N₂O management in mental health facilities. You’ll need to maintain ambient storage temperatures between 20°C-25°C (68°F-77°F), while tracking ambient humidity and regulating lighting conditions to prevent thermal instability. For liquid N₂O systems, guarantee refrigeration stays within 0°F-10°F (-20°C–13°C). Careful temperature monitoring is especially critical since inert gas exposure can significantly impair human thermoregulation in cold conditions. Regular inspection of seal integrity helps prevent dangerous decomposition reactions that could lead to catastrophic pressure spikes.

Install continuous temperature monitoring systems with automated alerts to detect any deviations. You’ll want backup sensors for redundancy and quarterly calibration schedules to maintain accuracy. Keep your storage areas away from direct sunlight and heat sources, as temperatures must never exceed 125°F (51.67°C). When tracking pressure changes, pay close attention to gradual shifts caused by environmental fluctuations. Remember to secure all monitoring equipment and restrict access to authorized personnel only.

Staff Training and Safety Protocols

Effective management of nitrous oxide facilities requires thorough staff training alongside sturdy monitoring systems. You’ll need to implement extensive training programs that cover proper breathing techniques, dosage titration, and continuous patient monitoring protocols. Staff must complete 8 hours online coursework and demonstrate competency through supervised clinical cases. Due to its nature as a party-like substance, nitrous oxide requires especially vigilant oversight in clinical settings.

Your staff scheduling protocols must guarantee trained personnel are always present during nitrous oxide administration. Train your team to perform regular checks on storage systems, including tank positioning, leak detection, and proper labeling of full versus empty cylinders. You must also maintain strict documentation of all training sessions and safety drills.

Equip your staff with emergency response knowledge, including leak containment procedures and primary care protocols. Make sure they’re well-versed in NFPA 99 standards and can operate mechanical exhaust systems effectively. Periodic compliance audits will help verify your team’s adherence to these critical safety measures.

Emergency Response and Containment Measures

When managing N₂O tanks, you’ll need a designated rapid response team with clearly defined roles for containing leaks and coordinating evacuations. You must install electronic leak detection systems that monitor gas concentrations and trigger automated alerts when levels exceed 25 ppm TWA. Your facility’s evacuation routes should direct staff and patients away from potential leak zones in the direction of predetermined assembly points, with routes clearly marked and regularly tested during safety drills.

Rapid Response Team Roles

Rapid response teams serve as the frontline defense against nitrous oxide emergencies in mental health facilities, requiring seamless coordination across multiple disciplines. Through established interdisciplinary protocols, these multidisciplinary teams must act swiftly and decisively when N2O-related incidents occur. Implementing rapid stabilization protocols from trauma care ensures immediate patient safety during nitrous oxide exposure events. Staff can deliver a 50:50 mixture with oxygen through controlled systems for safe sedation when needed. Early detection of adverse reactions requires teams to monitor for any vitamin B12 deficiency symptoms in frequent users.

- Psychiatrists and neurologists collaborate to assess patient mental status while monitoring critical signs and implementing emergency interventions

- Emergency response coordinators direct containment procedures, guaranteeing proper isolation of affected areas and activation of gas scavenging systems

- Clinical staff maintain continuous documentation of exposure levels, critical signs, and treatment outcomes

- Facility engineers provide real-time monitoring of ventilation systems and N2O infrastructure

You’ll need to guarantee your response teams regularly practice these protocols through simulated scenarios, maintaining readiness for potential emergencies while staying current with evolving safety standards and best practices.

Leak Detection Systems

Modern leak detection systems form the cornerstone of N₂O safety protocols in mental health facilities, integrating multiple technologies to prevent catastrophic releases. You’ll need to implement redundancy testing through NDIR cameras and ultrasonic sensors, ensuring backup power sources maintain continuous monitoring capabilities. Studies indicate that staff training programs significantly reduce leak incidents. Specialized cameras enable technicians to detect rare oxygen leaks in flange joint connections. The implementation of acoustic imaging technology allows for real-time visualization of gas leaks overlaid on digital photos for precise identification.

| Detection Method | Critical Functions |

|---|---|

| NDIR Cameras | Detect leaks 0.67-12L/min |

| Ultrasonic Sensors | Identify high-frequency sounds |

| Pressure Testing | Monitor 15-min intervals |

Your facility’s leak detection protocol must include regular pressure monitoring with 20% threshold alerts, while maintaining consistent ambient temperatures for accurate readings. By combining digital and analogue gauge comparisons with routine infrastructure inspections, you’ll create a substantial detection framework that identifies potential leaks before they become critical emergencies.

Evacuation Route Planning

Building upon sturdy leak detection measures, effective evacuation route planning forms the next layer of N₂O safety management. You’ll need to implement specialized route mapping that strategically avoids high-risk storage zones while guaranteeing multiple escape paths remain accessible during emergencies.

Your evacuation strategy should include:

- Gas-specific signage with standardized color coding and reflective directional markers

- Decentralized E-cylinder placement at least 30 meters from designated assembly points

- Alternative pathways that bypass dental suites and operating rooms, where N₂O is commonly used

- Pressurized barriers between storage areas and main evacuation corridors

Don’t forget to coordinate with local emergency services by sharing your facility’s evacuation maps and establishing clear communication channels. Regular staff training through quarterly drills ensures everyone comprehends their roles during a crisis.

Maintenance Schedules and Inspection Guidelines

You’ll need to implement rigorous daily safety checks of all nitrous oxide equipment, including visual inspections of cylinders, pressure tests of regulators, and functionality verification of emergency shutoff systems. Your documentation must track every inspection, maintenance action, and equipment replacement in detailed logs that meet current regulatory standards. To maintain compliance, you should establish a monthly review schedule for all safety protocols and documentation procedures, ensuring your facility adheres to EIGA Doc 33 and ISO 23208 guidelines.

Daily Equipment Safety Checks

Implementing rigorous daily equipment safety checks stands as the cornerstone of N₂O tank management in mental health facilities. You’ll need to follow a thorough visual inspection checklist and maintain strict flow meter calibration requirements to guarantee safe operations.

Your daily safety protocol must include:

- Examining N₂O tanks and connections for dents, rust, or leaks, and securing all connection points

- Verifying cylinder pressure against manufacturer specifications using calibrated gauges to detect variations exceeding 5%

- Checking pressure-relief valves for blockages or corrosion, confirming proper operation per OSHA standards

- Inspecting delivery tubes for cracks, fraying, or kinking, and replacing components at initial signs of wear

Always document your findings and immediately report any equipment irregularities to prevent potential safety hazards or dosage errors.

Monthly Regulatory Documentation Procedures

Detailed monthly documentation procedures form the regulatory backbone of N₂O tank management in mental health facilities. You’ll need to maintain detailed maintenance logs covering pressure tests, valve inspections, and leak detection surveys. Your technician training programs must guarantee proper certification for all staff handling these critical tasks.

| Inspection Type | Documentation Required | Frequency |

|---|---|---|

| Pressure Checks | Calibration Reports | Monthly |

| Valve Integrity | Torque Values & Seals | Monthly |

| Leak Detection | Survey Results | Monthly |

| Component Tests | PRV Function Data | Quarterly |

Track your tank storage conditions, including ambient temperature and ventilation rates. You’re required to monitor expiration dates for tanks stored between 6-12 months, guaranteeing alignment with safety protocols. Document all pressure gauge calibrations and maintain thorough records of emergency response drills and PPE inventory checks.

Regulatory Compliance and Documentation Standards

While managing nitrous oxide in mental health facilities requires strict adherence to multiple regulatory frameworks, NFPA 99 serves as the cornerstone for compliance standards. You’ll need to maintain thorough documentation for cylinder storage configurations and ventilation monitoring procedures, ensuring your facility meets strict safety protocols.

- Conduct quarterly exposure assessments using lapel-mounted sampling devices, documenting all readings within the NIOSH-recommended 25 ppm TWA limit

- Maintain detailed equipment logs tracking scavenging unit performance, leak tests, and demand valve functionality

- Document ventilation systems achieving 10 air changes per hour with proper low-wall intake and ceiling exhaust configurations

- Keep certification records proving staff completion of 8-hour coursework and supervised N₂O handling training

Your facility’s compliance depends on precise record-keeping and regular audits to validate adherence to these critical safety standards.

Safe Transport and Handling Procedures

When moving N₂O equipment through your facility, you’ll need to use approved transport devices like padded dollies while keeping the path clear of obstacles and personnel. You must secure all tanks in an upright position using appropriate restraint systems, including straps or chains that prevent any shifting during movement. If an emergency occurs during transport, you’ll need to follow your facility’s rapid-response protocols, including immediate valve shutdown and area evacuation procedures.

Moving Equipment Safely First

Before transporting nitrous oxide cylinders within mental health facilities, you’ll need to implement rigorous safety protocols that protect both staff and equipment. Establish routine maintenance schedules and designate appropriate storage locations before any movement begins.

When preparing to move cylinders, guarantee you:

- Conduct thorough cylinder inspections for damage and verify valve seal integrity using ultrasonic detection

- Use mechanical transport equipment like dollies or hand trucks, never dragging cylinders across surfaces

- Secure valve protection caps and maintain cylinders in an upright position during transport

- Document your planned route, avoiding heat sources and maintaining proper ventilation throughout

Always use flat-surfaced carts and limit the number of cylinders transported at once. Keep detailed transport logs and maintain clear labeling to safeguard safe, compliant handling during facility transfers.

Proper Tank Restraint Methods

Proper tank restraint forms the cornerstone of safe nitrous oxide handling in mental health facilities. You’ll need to implement vital tank stabilization requirements, including non-slip brackets and pressure-resistant holders designed for your specific transport vehicles and storage areas.

Always secure cylinders in an upright position using strap-based restraints and anti-rollback mechanisms to prevent lateral movement. Your failure mode anticipation should account for vibrational stress and potential cylinder shifts during transit. Install locking chocks and stabilizing platforms to maintain positioning integrity.

You must conduct pre-transport inspections of all restraint devices, verifying proper tension and secure mounting. Guarantee your staff are trained in correct restraint procedures, including regular checks of clamp integrity and strap tension. Don’t skip post-transport validation; it’s essential for confirming tanks remain properly secured after movement.

Emergency Transport Protocols

Five critical protocols govern the emergency transport of nitrous oxide tanks in mental health settings. You’ll need to integrate transport route planning and temperature regulation while adhering to strict safety measures during any tank movement. Before initiating transport, verify tank integrity and pressure readings to confirm safe handling conditions.

- Secure all tanks using approved restraint systems and guarantee your transport vehicle meets hazardous materials standards

- Maintain proper ventilation throughout the transport route to prevent dangerous gas accumulation

- Monitor ambient temperature during transport, keeping tanks between 50-75°F (10-24°C)

- Plan your route in advance, avoiding areas with excessive vibration or unstable surfaces

Remember to document all transport activities, including pre-transport checks and any incidents that occur during movement. Your strict adherence to these protocols helps prevent accidents and ensures regulatory compliance.

Risk Assessment and Mitigation Strategies

Thorough risk assessment forms the foundation of safe nitrous oxide management in mental health facilities. You’ll need to implement continuous quality improvement measures, including regular ambient N₂O monitoring and comprehensive occupational health monitoring protocols. Guarantee your facility maintains exposure levels below 25 ppm TWA through proper ventilation systems and leak detection.

Your risk mitigation strategy must incorporate multiple layers of protection. Install N₂O sensors in confined spaces, maintain strict temperature controls between 16-38°C, and keep tanks at least 15 feet from ignition sources. You’ll also need to conduct weekly cylinder inspections for damage and establish clear emergency protocols. Don’t forget to document all safety procedures, including regular staff training on rapid valve shut-off procedures and proper PPE usage, to maintain regulatory compliance.

Equipment Certification and Quality Assurance

Maintaining strict equipment certification standards forms the cornerstone of nitrous oxide safety protocols in mental health facilities. You’ll need to establish a thorough quality assurance program that includes regular audits for recertification and staff qualifications assessment to guarantee compliance with NFPA 99 regulations.

- Implement scheduled pressure checks and valve examinations, documenting all maintenance activities in your facility’s compliance system

- Verify that your ventilation systems meet required specifications, with floor intakes and ceiling exhausts properly configured

- Conduct monthly inspections of fire barriers, ensuring 1-hour rated walls and ¾-hour doors remain intact

- Test emergency backup power systems quarterly to maintain continuous safety controls during outages

Your facility must maintain detailed records of these certifications, as they’re essential for regulatory compliance and safety assurance during accreditation reviews.

Frequently Asked Questions

How Long Can Nitrous Oxide Tanks Be Safely Stored Before Requiring Replacement?

You’ll need to replace your nitrous oxide tanks within 6-12 months during prolonged storage duration, even under ideal conditions. While tanks can technically last up to 24 months, quality degradation becomes a concern after the initial year. You must follow strict tank inspection schedules every 6-12 months to assess gas integrity. Don’t exceed manufacturer-recommended storage periods, and you should always maintain temperatures between 16-38°C for maximum stability.

What Happens if Nitrous Oxide Accidentally Mixes With Other Medical Gases?

If you’re dealing with accidental gas mixing, you’ll face serious immediate risks. When nitrous oxide mixes with other medical gases, it can cause potential oxygen depletion in the delivery system, leading to dangerous hypoxic conditions. You’ll also encounter unsafe pressure build-up within the tanks, which could trigger system failures or ruptures. Don’t attempt to use mixed gases; shut down the system immediately and contact emergency services for proper handling.

Can Nitrous Oxide Tanks Be Stored Horizontally for Short Periods?

You shouldn’t store nitrous oxide tanks horizontally, even for short periods. While tank positioning may briefly shift during transport or hoisting, OSHA Standard 1926.350(a)(9) requires vertical storage at all other times. Storage duration isn’t a factor; the risks of valve damage, leakage, and content misidentification remain constant. You’ll need to maintain upright positioning and secure your tanks with proper brackets or chains to guarantee compliance and safety.

How Often Should Staff Undergo Recertification for Handling Nitrous Oxide?

You’ll need to complete mandatory recertification every 3 years according to OSHA/EPA standards, but don’t overlook the importance of ongoing training. You must participate in monthly competency evaluations and annual safety audits to maintain your certification status. If there are any technical or procedural changes to protocols, you’ll need immediate retraining. Always document your training sessions and maintain current Basic Life Support (BLS) certification throughout your handling period.

What Are the First Signs of a Compromised Nitrous Oxide Delivery System?

You’ll notice early warning signs of a compromised delivery system through several key indicators during compressed gas monitoring. Watch for unexpected hissing sounds near connections, visible gas plumes, or unusual pressure gauge fluctuations. Pay attention to rapid gas depletion that exceeds normal usage rates. For reliable leaks detection, monitor for sweet or metallic odors and check if your ventilation system maintains proper negative pressure in treatment areas.